Spitfire Doors are all powder coated and many customers request doors with an extra treatment, to add a sophisticated finish, like wood, concrete or carbon-fibre effect.

What is powder coating?

Powder coating was first developed in the 1950’s and is a dry finishing paint process used in many industries where a high quality, long lasting finish is required. Powder coating will retain its perfect finish for up to 20 years with negligible fading. Powder coating is noted for its resistance to chemicals, corrosion and weather.

Why choose to Powder Coat?

Since around 1980, powder coating has been increasingly accepted as the preferred industrial finishing process for many products, including residential entrance doors. The reasons for the conversion from wet to dry powder can be attributed to these key factors:

- Material utilization is much higher with powder, with 92%-98% of the powder being utilised versus an average of 60% when using an electrostatic liquid system. The remaining 40% of liquid paint is toxic and has to be carefully disposed of.

- Powder is not considered hazardous waste, so the cost of disposal is minimal.

- Air used in the powder coating spray booth is returned directly to the plant, eliminating heating and cooling costs.

- The cured powder finish is less susceptible to damage than a liquid finish. There is less need for repair work on the finished item. This results in the need for much less elaborate packaging saving time and cost on re-working and packaging.

- Epoxy, acrylic, and hybrid powders provide excellent adhesion and offer improved resistance to chipping, abrasion, corrosion, and chemicals.

- Polyester powders provide additional advantages in ultraviolet and weathering resistance.

- Stringent regulations are being aggressively enforced in an effort to control air pollution and hazardous waste disposal.

- Powder coating eliminates solvent fumes from spray booths and oven exhausts that pollute the air.

- Potentially toxic sludge from liquid paints could contaminate the earth and must be disposed of as hazardous waste.

Every Spitfire door has a powder coated paint finish because it is such a high-quality, durable finish and the painting process is relatively environmentally friendly. This advanced process is available in an almost limitless range of colours and textures, and technological advances have resulted in exceptional performance, which allows us to give a long warranty on our doors, with confidence.

Because powder coated finishes are so tough, they are used on thousands of products that we come into contact with every day. Powder coating is used to protect equipment like JCB’s and aeroplanes, as well as everyday household products like doors and windows. This exceptional finishing process is more durable than a liquid paint finish and is much more resistant to fading or degradation when faced by attack from impact, moisture, chemicals, ultraviolet light or extreme weather conditions. This coating therefore reduces the risk of scratches, chips and corrosion. In summary, a powder coated Spitfire Door looks fabulous, the paint is consistent across the door and frame and the finish will last a very long time.

All of the powders used in the powder coating process are non-toxic, non-volatile and completely safe. Powder coating has no known short or long-term health risks and does not pose a fire risk.

A summary of the key benefits of powder coating

Durability – powder coating is extremely durable which means your Spitifre door will withstand the elements and will stand up well to daily use

Corrosion Resistant – salt, moisture and humidity attack metal. Powder coating provides a protective barrier that helps prevent corrosion.

Chip Resistant – unlike other treatments that can easily crack, peel, chip, scratch and corrode, powder coated aluminium doors are much more durable and will withstand the weather better

Zero Maintenance – because of its durability and resistance to abrasion and corrosion, powder coated aluminium requires virtually zero maintenance. Just a wash down with warm soapy water once a month will ensure that you Spitfire Door will look good for more than 20 years.

Long Lasting, Colour Fast Finish – powder coating is a durable finish that is tougher than conventional paint. Because of this, colours stay brighter and more vibrant for longer than conventional paints.

Environmentally Safe – the powder coating process has very little impact on the environment. No harmful solvents are used and powder coating does not emit vapours or fumes like liquid paint.

10 Year Warranty – a ten-year warranty is only possible because the quality of powder coating is so high and consistent

What is Decoral®?

Decoral® is a patented process for Decorating Aluminium, based on Sublimation, which is a physical-chemical process; the direct transition of a substance from the solid phase to the gas phase. Such technology is also called a ‘Heat-Transfer Process’.

The basic requirement being that Spitfire Doors aluminium profiles and aluminium sheets can resist a temperature of 200° Celsius in an oven for 10 minutes with no deformation.

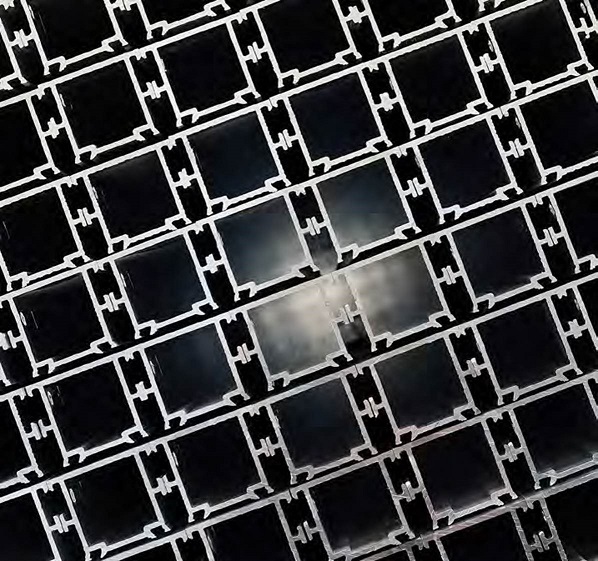

Using the Decoral® process, countless effects and patterns such as woodgrains, concrete or granite can be transferred onto the aluminium surface of our profiles.

In order to apply the Decoral® process, first all profiles must be powder coated and cured. Then a Decoral® heat transfer film, carrying the desired effect is wrapped around the profile. This sublimination film is printed with special inks which can replicate for example a woodgrain effect. Then the wrapped profile is placed inside an oven for 10 minutes and whichever effect is on the film will be burnt into the powder coated finish. The final finish will faithfully replicate the effect that was previously on the sublimated foil.